Just how serious is the shortage of skilled aviation technicians for the airline and MRO industries? According to labor experts, it’s very serious, and due to get worse.

Take North America: In its January 2023 report entitled, ‘Not Enough Aviation Mechanics’, the management consulting firm Oliver Wyman said that, “While there were just enough to handle the maintenance, repair and overhaul (MRO) workload on the North American fleet in 2022, our latest forecast suggests that a shortfall of somewhere between 12,000 and 18,000 is likely to be the case in 2023. By 2027 — projected to be the worst year for the shortage — the bleakest scenario has the supply deficit at more than 48,000 aircraft maintenance workers, or a shortfall of about 27%.”

Nulton Aviation

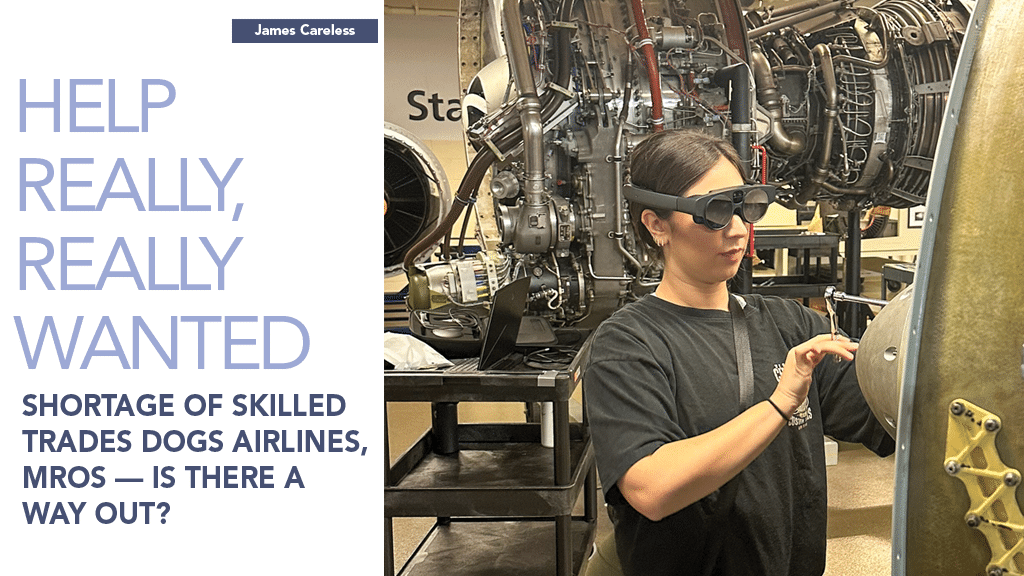

These bleak predictions didn’t come as a surprise to Oliver Wyman aviation practice partner and report co-author Derek Costanza. “We’ve been talking about a shortage for some time now,” he told Aviation Maintenance magazine. “We predicted this shortage back in 2017 or 2018 for the middle of this decade or sooner, and now here we are.”Oliver Wyman isn’t alone in reporting this trend. “In a recent survey, it was cited that 77% of aviation maintenance technician schools reported a shortage of aviation mechanics and 50% of employers reported difficulty in finding qualified mechanics,” said Dr. Larry Nulton, owner of Nulton Aviation, a flight training school and fixed-base operator (FBO) at the John Murtha Johnstown-Cambria County Airport in Pennsylvania. “This national trend can be observed throughout Pennsylvania as well.”

“All indications are that there is a significant shortfall of technicians across the entire industry,” agreed Charles Horning, director of Regulatory Compliance and Outreach at Embry-Riddle Aeronautical University in Daytona Beach, Florida. In order to attract talent to their shops, “some companies have recently increased wages as well as providing incentives for new technicians to come work for them,” he said. “The competition for technicians has obviously significantly increased in the last couple of years.”

There are many factors contributing to the shortage of technicians in the aviation industry. There are also many solutions available to address this shortage, according to the experts who spoke to Aviation Maintenance for this article. Here is what they told us.

Boomers Retiring, Encouraged by COVID

One major reason why the aviation industry is short of technicians is because the Baby Boomers are retiring. They are leaving the profession at a time when demand for their services is going up, thanks to the recovery of airline travel following COVID-19. Unfortunately, the remaining supply of skilled technicians is not sufficient to keep up with demand.

This retirement-based shortage has been predicted for some time by consultants such as those at Oliver Wyman. But the severity of the shortage has exceeded these predictions, due to the impact of COVID-19 on the labor market. “When the COVID-19 lockdowns happened, many mechanics and technicians left the industry,” said Armel Jezequel, director general/COO at Vallair, an MRO/aircraft recycler with facilities in France and Luxembourg. “They have not returned.”

According to the Aviation Technician Education Council (ATEC), about 30 percent of aircraft technicians in North America are at or close to retirement age and they’re retiring faster than they’re being replaced. “The average age of an aviation mechanic is 51,” said Crystal Maguire, ATEC executive director. “More than a quarter of them are older than 64 years.”

Demand for Technicians is Increasing as Air Travel Grows

As Baby Boomer technicians retire, the airline industry they serviced continues to grow. Based on data from Boeing’s Pilot and Technician Outlook 2022-2041 report, 610,000 new maintenance technicians will be needed to maintain the global commercial fleet over the next 20 years, to keep up with current market demand plus projected growth in global aviation travel.

“In the North American region alone, fleet growth is anticipated to be at a rate of 1.8% annually over the next decade,” said Sajedah Rustom, CEO and board director at AJW Technique, an MRO based in Montreal, Canada. “This is because airline flight schedules are increasing as travelers take to the skies.” At the same time, regions such as China have now opened for travel again and flights to this country are in demand, she observed. Many airlines are also expanding their fleets and mission profiles, and actioning previously neglected interior refurbishments and delayed maintenance scheduling due to COVID.

“Boeing’s Pilot and Technician Outlook 2022-2041 report noted that there will be a demand for over 610,000 new maintenance technicians over the next 20 years,” said Dr. Nulton. “Well, we are seeing this growing demand already occurring in Pennsylvania with an annual projected growth rate of well over 3% annually, and an estimated 455 job openings due to replacement needs and industry expansion.”

ATEC’s 2022 Pipeline Report paints a similarly dramatic picture. “The mechanic pipeline will need to increase production by at least 20% to meet projected workforce demand,” it said. “In comparison, AMTS (aviation maintenance technical school) enrollment is growing only about 2% a year.”

“The Boeing Pilot and Technician Outlook is a little narrow; it only looks at commercial fleets,” ATEC’s Maguire said. “As new mechanics, our students support all sectors of aviation, not just commercial.”

Not Enough New Blood

The two percent/year increase in AMTS enrollments is the third factor driving the aviation technician shortage. Simply put, there’s not enough new blood coming into the industry to replace the old blood going out. And, of course, the pandemic only made matters worse.

“At the height of COVID, there was a reduction in the number of aerospace technicians being trained and this shortage put pressure on the aviation supply chain,” said Rustom. “This has led to longer lead times for maintenance and repairs, which in turn is affecting flight schedules.”

Today, “the trend of not enough people training to be aircraft mechanics to start with is having a big impact,” Jezequel added. “In addition, there are not enough training programs available globally to meet the demand for aircraft mechanics. This can be due to a lack of funding or resources, or lack of interest from potential students.”

One factor depressing enrollment in AMTS programs is a widespread and long-standing public bias against “blue collar” jobs. In countries like the United States, decades of societal pressure to “send your kids to college so they can get high-paying positions” has prejudiced some parents and students against skilled careers in the trades — even though such jobs can be equally lucrative and long-lived.

“One of the greatest challenges is getting the story out that a career in aviation maintenance can be great,” Horning said. “There may be some stigma to taking a blue collar/trade track, but I think a larger reason is that there is not a good understanding within the general public of what it means to be an aircraft technician and what that career path can look like.”

His opinion is endorsed by Brian Prentice, another of the Oliver Wyman report co-authors and one of its transportation practice partners. “I do think that we as an industry need to do a better job of communicating and marketing, and letting people know what a great career in aviation maintenance can be,” said Prentice. “But I also think society as a whole should be focussing on what are the right paths for young workers entering the workforce. And that isn’t always a four-year college degree. Sometimes that is a technical degree, and a very attractive and rewarding career in aviation maintenance.”

For society to make this change, people will have to re-set some of their social status beliefs. They will also have to base more of their attitudes on facts rather than snap judgements. For instance, “we are seeing inaccurate environmental perceptions of the aviation industry is having a large impact on people not training to be aircraft mechanics,” Jezequel said. “The industry is perceived as not having a ‘green future’ by those not already working in it, despite aviation companies working towards achieving net zero pollution levels in the next 20 years.”

Tackling the Shortage Head-On

Changing the public’s negative perception of aviation technician careers will require efforts by the industry and AMTS schools like. The reason? “The industry is best at showing what a technician does,” said Horner. “The schools can most effectively explain how to make that happen by becoming an FAA-certified mechanic.”

As far as ATEC’s Maguire is concerned, an effective way to tackle the labor shortage head-on is to promote aviation technician careers to students in school. “People who just don’t know about the trades in general tend to focus on getting four-year college degrees,” she explained. “So you have to reach them in middle school to spur their interest, because most people these days are choosing their career paths before they get to high school.”

This is why most of ATEC’s efforts into workforce development are going into creating awareness among prospects in middle school. “We are also working to build high school programs that can partner and build pipelines into our network of FAA-certificated schools to help increase their enrollment,” said Macguire. “In the United States, many AMTS have empty seats in their programs, so there is room to handle this expanded influx of students.”

On the industry side, Vallair is doing its part to boost the supply of new aviation technicians. To this end, “we are partnering with aircraft academies to offer easy-to-access qualifications to employees,” Jezequel said. “In line with this, we offer competitive salaries based on the specialist skill set of candidates. We also work alongside local schools and colleges to highlight the benefits of a career with Vallair in the aviation industry, showing the next generation the positives of working as an aircraft mechanic and dispelling negative perceptions of the industry.”

In Pennsylvania, the planned 138-acre aviation-centered Mid-Atlantic Opportunity Park will partner with Nulton Aviation Services to train new aviation mechanics. “With nearly 304,500 total jobs linked to Pennsylvania’s airport system, there is a high demand for skilled aviation mechanics, and the Laurel Highlands region also offers abundant opportunities for high-paying careers in this industry,” said Dr. Nulton.

To further address the technician shortage, Saint Francis University recently expanded its existing relationship with Nulton Aviation Flight Academy, to give access to SkyWest’s Elite Pilot Pathway and Aviation Maintenance Training Pathway programs. “In addition, Nulton Aviation Services is spearheading an effort to approach and get approval from the Pennsylvania Department of Education to launch six aviation CIP (Classification of Instructional Programs) codes — with one being airframe and powerframe mechanic training,” he said. “Using these newly approved codes, we will be integrating the aviation curriculum into the high school curriculum, providing a strong foundation for future aviation mechanics. Collectively, these initiatives demonstrate a proactive approach to address the aviation mechanics shortage and create more opportunities for high-paying careers in aviation.”

Oliver Wyman’s Not Enough Aviation Mechanics report has further ideas to attract more students to AMTS and, from there, into the aviation industry. One way to do this is by re-engineering the working environments of aviation technicians to align with the values of Generation Z (Gen Z; people born between 1997 and 2013) job candidates.

For instance, “Diversifying the workforce and valuing diversity are steps in the right direction, given that Gen Z workers look for and expect diversified workforces,” said the Oliver Wyman report. “Gen Z workers are also apt to leave a work situation where they encounter unfair pay or uneven treatment based on race or gender. The atmosphere at work is also important to these younger employees who work to live rather than live to work as their baby boomer elders did. … The MRO industry offers few of the amenities common at companies popular with Gen Z workers, such as free snacks, comfortable break rooms, and attractive work environments. Gen Z employees expect these extras when they come to work — especially since hybrid work situations are not available in MRO.”

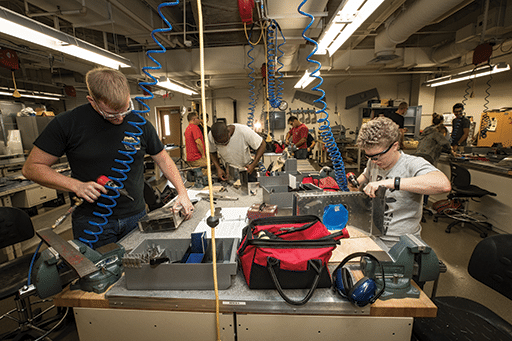

In the same vein, the training process associated with becoming an aviation technician has to be updated to meet Gen Z demands, or they will simply avoid aviation in favor of those industries that do. To this end, “The FAA could help the industry by making some rule changes that would modernize the sector,” the Oliver Wyman report said. “Revising 14 CFR Part 147, effective September 21, 2022, was a step in the right direction by removing archaic requirements from training. This was a much-needed overhaul to align curriculums with current industry standards. But the change shouldn’t stop there. The FAA and the industry could also consider ways to reduce the time mechanics spend in the academic environment through the expansion of on-the-job work study where candidates can work with A&P license holders.”

That’s not all. To boost AMTS enrollment and graduation levels, the Oliver Wyman report calls for increased “government subsidies and free tuition programs for AMT schools with requirements that students then owe a certain amount of time on the job in the United States or North America, like the military requirements for Reserve Officers’ Training Corps candidates.” It also recommends allowing aviation technician candidates to apply credits earned in other trades towards their certificates where appropriate: “Amend the rules that require 18 full months of 40-hour weeks to allow candidates that put in the same hours over a shorter period to qualify to take the A&P exam”, and, “Make it easier for military-trained and foreign aircraft mechanics to get certificated as A&P-licensed mechanics in the U.S. and make work visas available to them.”

As well, Gen Z is a truly digital generation, so their AMTS training process needs to offer “a blended environment of in-class, online, and hands-on training,” said the report. “Today’s younger generation also grew up around technology, and they expect — and want — to utilize technology in their workplace, even for jobs that are hands-on. MRO training and operations must incorporate more modern technologies and experiences, not as experimental pilots but as business as usual. For instance, to ensure a unified industry focus on safety and reliability, training on the use of electronic logbooks, portable devices for work instructions, and hyperlinked content management systems should become standardized.”

Finally, while doing all it can to increase the number of new technicians going forward, the aviation industry has to do whatever it can to retain those it already has. After all, a Boomer who hasn’t retired yet is one who doesn’t have to be immediately replaced. This means “offering flexible working solutions to seniors verging on retirement in the form of part-time consulting, training, and teaching opportunities to ensure the technical foundation of the business is strong,” said Rustom, while at the same time “raising up emerging talent with a strong employer value proposition, diverse training programs, captivating culture, and digital enablement is at the core of sustainable success.”

One thing is certain: The growing shortage of skilled aviation technicians is not a problem that can be cured with a quick fix. Addressing it successfully for the long-term as air travel grows and the Baby Boomers retire requires “a longterm process in which we have to consider the short, medium and long-term objectives of the company as well as its growth ambitions,” Jezequel observed. “In doing so, the aviation industry has to maintain high standards to meet customer demand on a day-to-day basis.”

Is this doable? In Pennsylvania, according to Dr. Nulton, the answer is yes.

“Our efforts are having a positive impact in addressing the shortage of aviation mechanics,” he told Aviation Maintenance. “By providing education and training programs, high school education opportunities, apprenticeships and on-the-job training, we are attracting and preparing new workers to enter the field of aviation mechanics. We are also promoting the benefits of careers in aviation mechanics and other high-demand fields to younger generations to encourage enrollment and interest in these careers. We are confident that these efforts will pay off in the coming years by creating a strong workforce pipeline that can fill the demand for aviation mechanics and support the growth of industries in the region.”