Boeing Global Services has teamed up with Pacific Tool to offer production-proven tooling solutions to commercial airline and MRO businesses worldwide.

Boeing Global Services has added the Pacific Tool production standard tool (ST) catalog to its offerings. ST tools provide tip-to-tail production and repair solutions that improve safety and efficiency while ensuring the highest levels of quality.

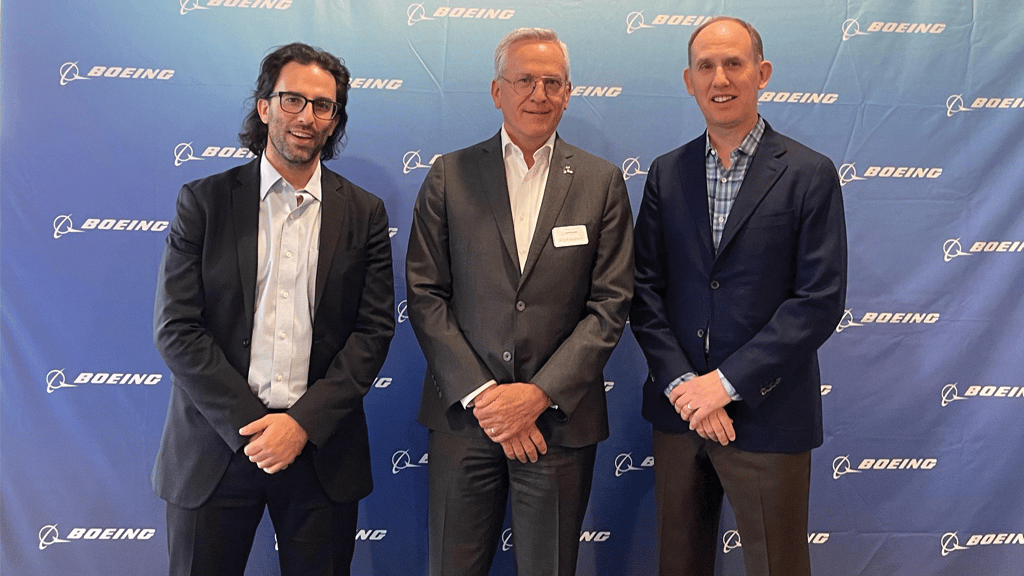

“Pacific Tool has been supporting Boeing’s production with specialized tooling since 1966, and we’re very excited now to be able to bring these great Boeing designs to airlines and MROs through Boeing Global Services,” said Chris Jenne, Pacific Tool vice president, Aftermarket Business Development. All 25,000 Pacific Tool items conform to relevant Boeing requirements.

“Our alignment with Pacific Tool builds upon our commitment to customers to keep their fleets flying safely. Many of the Pacific Tool products are the same tools used every day in Boeing factories to build new aircraft, and we look to continue to provide OEM-quality maintenance products and solutions to aerospace customers across the globe,” said Travis Sullivan vice president and general manager of Distribution Services, Boeing Global Services.

Pacific Tool has more than 55 years of experience with Boeing production systems and platforms, bringing customer solutions that leverage the requirements of factory production efficiency for day-to-day maintenance operations. In an ever-competitive maintenance market, efficiency is a priority. Pacific Tool products help to get more work done faster and safer.

“A partnership like this makes total sense. We’re bringing Boeing solutions directly to Boeing customers through Boeing Global Services,” says Lee Falck, co-owner of Pacific Tool. “Airlines and MROs have been waiting for this kind of help, and we’re glad to be a part of a new way for the aftermarket to get the support they need.”