A global engineering solutions firm for the aerospace industry is set to showcase innovations at the Farnborough International Airshow.

Barnbrook Systems, of Hampshire, UK, will unveil new and upgraded technology and services when it attends the world famous event for the 14th consecutive time in July 2024.

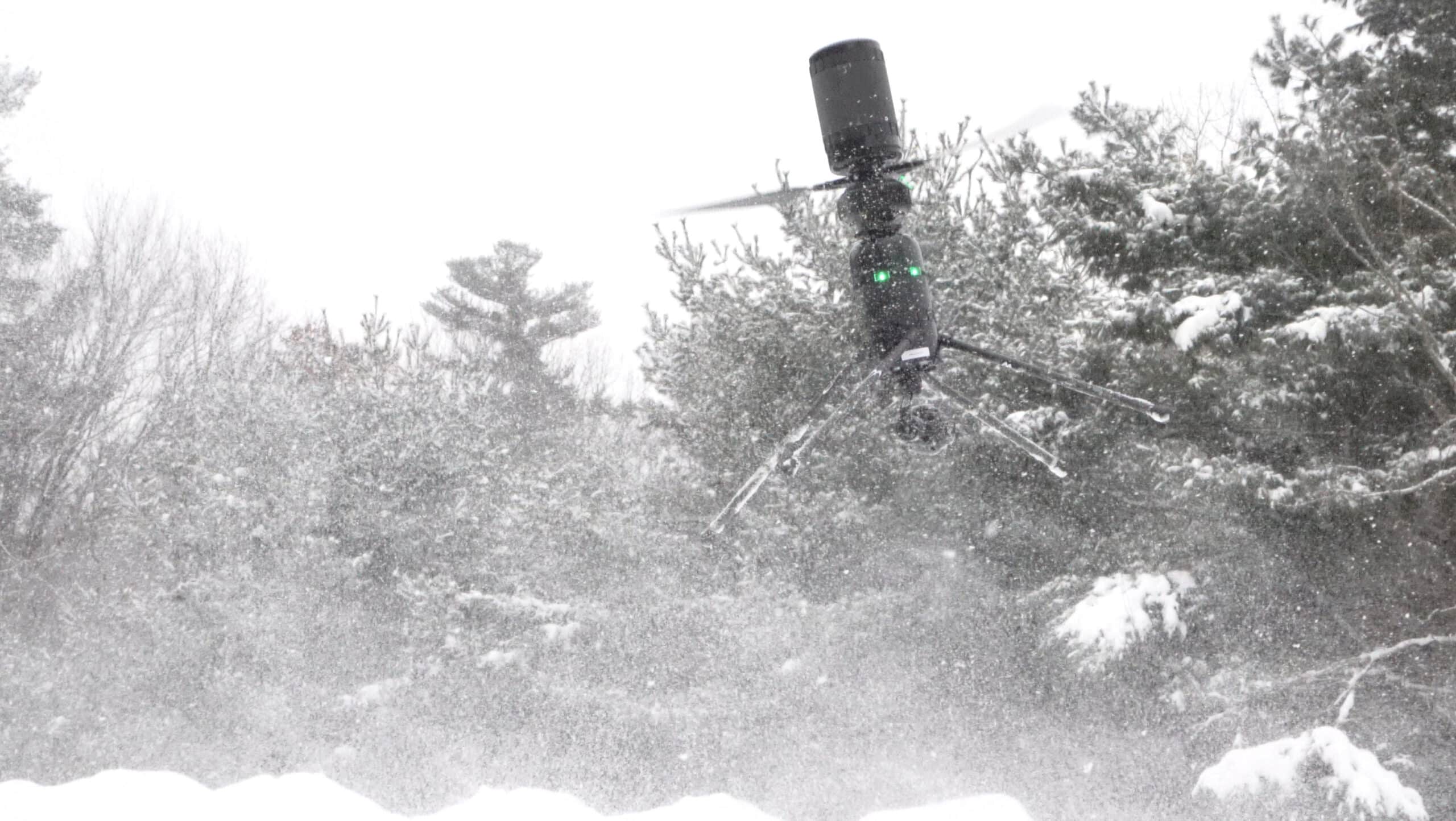

They will include its market-leading refueling switch for helicopters and the next generation of its BlueCube remote monitoring systems.

Its team will also unveil more details about its work on hydrogen energy solutions, fire suppression systems, ultra-high pressure monitoring ranges and innovations in AI and machine learning.

“All at Barnbrook Systems are excited about this year’s airshow,” said Andrew Barnett, director at Barnbrook. “We may have been attending this event for nearly 30 years but we are also a modern, forward-thinking company which focuses on growth and continuous improvement through creativity and innovation. We are looking forward to showcasing our new and upgraded engineering systems aimed at delivering bespoke solutions to meet myriad requirements of today’s aerospace, aviation and defence sectors.”

Barnett, who is member of the board at Farnborough Aerospace Consortium (FAC), added: “Sustainability and the drive to net zero are proving to be major dynamos as the pace of the digital revolution continues to accelerate. We’re keen to demonstrate how our applications, including our work on hydrogen projects, can harness the power of change at the airshow and share ideas with other innovators from across the world.”

Independent, family owned Barnbrook Systems will be in the main hall at the airshow on July 22 to 26. It will be on stand 1317, close to the FAC marquee.

It recently won a repeat, six-figure order in for its inflight refueling switch for aerospace giant Leonardo. The first deal for this system was signed at the 2016 airshow.