Suppliers, MROs and operators have announced new developments in their maintenance activities and laid out plans for expanding services that support repair, overhaul and inspection efforts.

The latest developments range from new offerings of inspection and maintenance tools and software, parts manufacturer approval (PMA) and supplemental type certificate (STC) initiatives for business jets and expansion of airline spares inventory and maintenance base operations. Here’s a rundown.

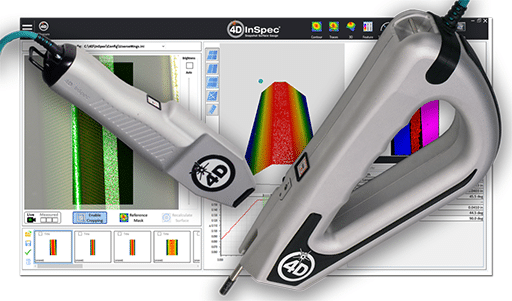

4D InSpec AT’s Use in Engines Grows

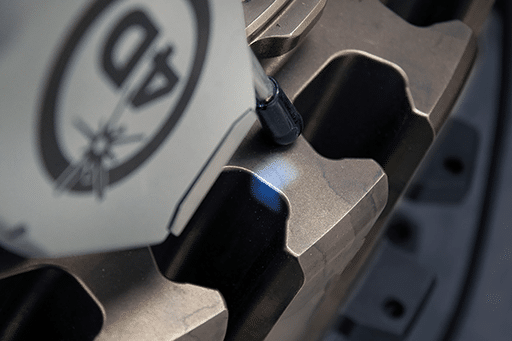

4D Technology’s 4D InSpec AT fully automated, non-contact, 3D surface gauge will be measuring specifications, damage and wear on more aircraft engine parts following a recent customer order.

The 4D InSpec AT is compatible with automated systems like robot arms and rotary tables. Combined with a robot arm, the gauge provides a substantial increase in productivity and precision for customers measuring edge break, chamfer and round-off on aerospace parts, the company says. With the gauge rapidly positioned by a robot arm, the 4D InSpec software can take a measurement, calculate adjoining planes and determine the shape, curvature and slope of the remaining surface after edge break and round-off. (The 4D InSpec AT also can be used as a handheld instrument.)

This allows customers to check critical specifications of aircraft and engine parts like airfoils, disks and bearings, as well as to prevent crack propagation and ensure proper fit and seal. The 4D InSpec can help overcome difficulties in measuring the numerous callouts on an engineering drawing, such as hard-to-reach inside corners, areas between blades and samples that must be perpendicular to adjoining edges.

In addition to measuring machined edges, aircraft mechanics and inspectors use the device to assess wear, scratches, dents, corrosion and other damage that occurs in aircraft engine operation. It can assess features ranging from 0.1 inch to 100 mils deep or tall. The measurements—completed in seconds on the shop floor or on-wing — quickly determine whether critical parts are safe for use or need to be discarded.

For engine parts makers, the 4D InSpec’s short measurement-to-measurement time of — about a second — means they can save hours over tedious preparation of rubber replicas for feature assessments.

“The aerospace industry has some of the most stringent parts specifications found in any macro-scale manufacturing process,” 4D Technology general manager, Erik Novak, said. The selection of 4D InSpec “validates the precision of our measurement and the great value added by its speed and versatility.”

Based in Tucson, Arizona, 4D Technology is a leader in innovative products for measuring surface quality and defects on precision surfaces. The company is a wholly owned subsidiary of Onto Innovation Inc.

Snap-on Kit Reliably Moves Impact Tools

Snap-on Industrial’s Portable Heavy-Duty Impact Sets help technicians reliably transport their impact tools on the work site.

The 25-piece, heavy-duty cordless impact set with portable storage (425IMCT) comes with an assortment of tools, including:

• A 17-piece shallow-impact socket set with Snap-on Flank Drive technology, which provides superior gripping power while guarding against rounding of fasteners.

• A ¾-inch drive swivel-ball impact universal joint.

• ¾-inch drive extensions of three inches, seven inches and 10 inches.

• An 18-volt, ¾-inch drive Monster Lithium cordless impact wrench set, with 1,300 foot-pounds (1,763 Newton-meters) of bolt breakaway torque and 1,000 foot-pounds (1,355 Newton-meters) of working torque; the set includes two Lithium 5.0 amp-hour batteries and a charger.

• A sturdy, all-weather-resistant Pelican case with a collapsible handle and rugged wheels.

• Two-toned (red and black) colored tool control foam to securely house the tools.

The kit weighs 72.13 pounds (32.72 kilograms). The case measures 24.8 by 19.7 by 11.9 inches (62.99 by 50.04 by 30.23 centimeters).

The kit is sold through Kenosha, Wis.-based Snap-on’s franchisees and its company-direct, distribution and web-based channels. For more information on the kit, visit https://b2b.snapon.com/.

Performance Plastics Expands EnduroSharp Line

Performance Plastics has expanded its EnduroSharp line of aircraft maintenance tools, adding Torlon sealant removers, three EnduroSharp adhesive reamers and the Deluxe EnduroSharp Scraper Blade Sharpener for keeping those and other tools well honed.

The sealant removers are non-metallic, spiral single-fluted cutters designed to cleanly remove non-metallic debris such as cured sealants, fillers, coatings and adhesives from larger surface areas such as fuel tanks with no abrasion to the underlying paints, primers or metal substrates. Designed for use with a power drill, the cutters have a hex-drive mounting feature.

The cutters are made of Torlon, a material that itself can be re-sharpened. This makes the cutters and other tools made of Torlon reusable.

The multi-fluted, straight-walled adhesive reamers can be used to remove debris such as cured sealants and adhesives from fastening and bushing holes in metallic or composite structures without damaging the structures. Originally offered in nine sizes, the company has added three sizes to the lineup: the TAR 171 (0.171-inch diameter, straight-fluted, ¼-inch hex drive), TAR 234 (0.234-inch diameter, straight-fluted, ¼-inch hex drive), and TAR 296 (0.296-inch diameter, straight-fluted, ¼-inch hex drive). The reamers are also made of Torlon and are reusable.

The Deluxe EnduroSharp Scraper Blade Sharpener features a diamond abrasive material surface for sharpening and restoring a factory edge to all EnduroSharp consumable products. The diamond abrasive material itself can be resharpened.

Performance Plastics developed all EnduroSharp aircraft maintenance tools with the University of Dayton Research Institute (UDRI), and the Air Force Research Laboratory (AFRL) to provide reliable and dependable material removal tools for military and commercial aircraft maintainers.

EnduroSharp tools are approved for use by the U.S. Air Force, Marine Corps and Navy and military organizations of many other nations.

Performance Plastics is a Pexco company. Headquartered near Atlanta, the Georgia-based Pexco is a custom precision injection molder of high-performance, tight-tolerance thermoplastic components. It specializes in geometrically complex precision parts that consist of chemically inert materials. The company’s expertise led to the development of the patented EnduroSharp line of aircraft maintenance tools.

For more information, visit www.endurosharp.com.

Streamlight Unveils Brighter Tactical Light

The high-performance lighting maker Streamlight has introduced the ProTac HL6, the newest and brightest addition to its line of tactical lights.

The ProTac HL6 features a multi-function, easy-access head switch that allows for one-handed operation of the light’s momentary, variable intensity or strobe modes. It also has an anti-roll face cap and a sure-grip rubber sleeve.

The system includes a charge cord and two Streamlight SL-B48 5000 milli-Amp-hour lithium-ion rechargeable battery packs with an integrated USB-C charge port.

“The ProTac HL 6 is like a handheld flood light, allowing users to see all around them while also providing a powerful beam reach to put more light on a target at a distance,” said Michael F. Dineen, chief revenue officer of Eagleville, Pa.-based Streamlight. He said it is the ideal light for many uses, including troubleshooting repairs under low-light conditions.

The ProTac HL6’s high setting delivers up to 5,300 lumens and 80,000 candela over a range of more than 1,850 feet (566 meters). On medium, it produces 1,500 lumens, 23,000 candela and a 990-foot-plus (303-meter) beam distance. On low, the light provides 450 lumens and 6,700 candela over nearly 540 feet (164 meters). Streamlight said the ProTac HL6 can run for 12 hours and 30 minutes on low to two hours on high; in strobe mode, the light can run for four hours.

The ProTac HL 6 measures 10.5 inches (26.7 centimeters) in length and weighs 1.3 pounds (0.6 kilograms) with two SL-B48 rechargeable batteries. It is rated IPX7, making it waterproof to one meter for 30 minutes. The light also is impact resistance-tested to 3.28 feet (one meter). It comes with Streamlight’s limited lifetime warranty.

For additional information, call +1-800-523-7488, visit streamlight.com or connect on facebook.com/streamlight, Instagram.com/streamlightinc or LinkedIn/company/streamlight-inc.

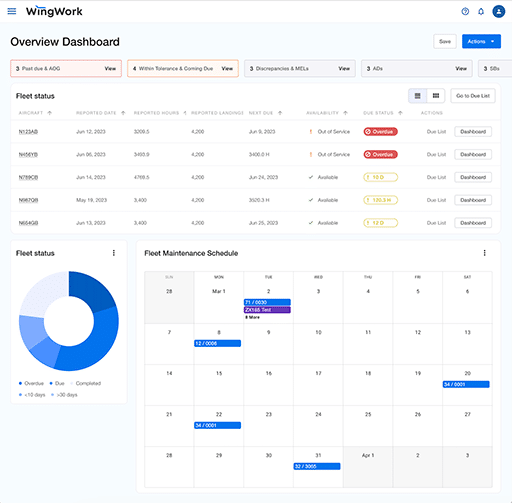

New Part 91, 135 Maintenance Tracking Software

Miami-based WingWork has launched its cloud-based maintenance tracking platform for Part 91 and 135 mechanics.

With a modern, intuitive interface, the WingWork platform is designed for ease-of-use and comprehensiveness, the company said, allowing operators to spend more time fixing and less time clicking. The initial launch has features covering maintenance tracking, work orders, inventory control, invoice generation, logbook ingestion and data entry. WingWork said its goal is to empower operators to better forecast maintenance events and associated costs, reducing downtime spent servicing their aircraft.

WingWork said it tapped a team of 50-plus industry advisors, including maintenance personnel at operators and seasoned aviation experts, to develop the platform.

“Our network of advisors has been a crucial element to our success,” said CEO Matt Castellini. “They give us invaluable feedback on building a world-class tool to power the modern aircraft mechanic.”

The WingWork team plans further product expansion driven by customer feedback.

“The maintenance industry is ready for a 21st-century solution that will utilize cutting-edge technology widely adopted in other industries,” WingWork chief technology officer Karthik Srinivasan said. “We want to develop best-in-class software to help the maintenance industry make the transition from relying on manual processes to harnessing the power of next-generation technology.”

For more information, visit www.wingwork.com.

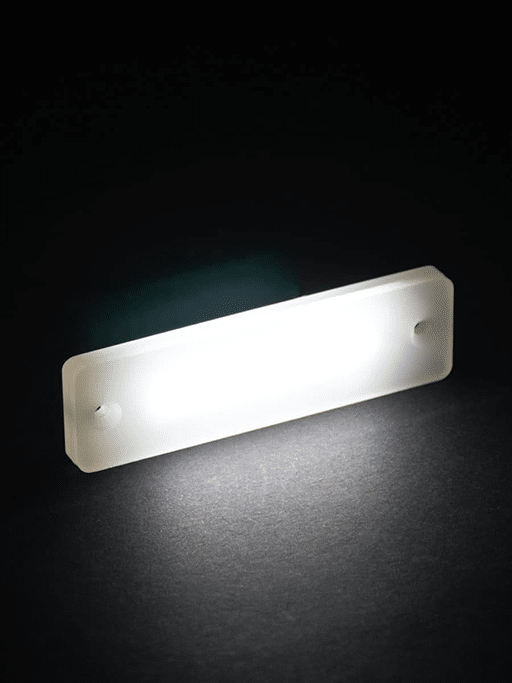

PWI Gets PMA for Citation LED Step Lights

Wichita, Kan.-based PWI, Inc. is bringing the long life and low power-draw efficiency of LEDs to Cessna Citation jet steps with its receipt of PMA on components for that Textron Aviation series of aircraft.

The Citation models covered by the PMA include the Citation II, the 550 Bravo, the S550 II/SP, the Citation V 560, the Excel 560XL and the 650, as well as the Citation III, VI and VII.

The new LED step light replaces the original incandescent step lights in the door of the Citation (part number 6900163-000 and Textron part number 1021LIGHT). No aircraft modifications are required, according to PWI. It says the single PWI LED part number (6910163-003) simply screws into the steps using the original mounting holes. The installation reuses the original aircraft lighting wiring and runs on the aircraft-supplied 28 volts. All PMA-approved LED cabin lighting systems have a three-year PWI warranty.

The door-mounted step light is designed to resist cabin ingress and egress wear-and-tear. The new design uses impact-resistant polycarbonate lens material to deliver long-term durability. It also offers greater liquid and contaminant resistance to such common elements as deicing fluid, rain, snow and mud, PWI said.

“This new LED step light puts a nice touch on one of the first things you notice when entering the cabin: the doorsteps,” said PWI president and CEO Robi Lorik. The PMA installation “adds a level of safety and convenience that passengers appreciate before they are seated.”

PWI has been an original equipment manufacturer of fluorescent cabin lights for the Citation as well as other business jets (Dassault Falcons, Gulfstreams, Challengers and Learjets) and King Air turboprops for decades. PWI FAA-approved LED aircraft lighting upgrades can be purchased direct or through its authorized dealer and distribution network. Contact PWI at +1-316-942-2811 or sales@pwi-e.com.

Skyservice Targets G280 Gogo Galileo STC

Skyservice Business Aviation is developing an STC to install Gogo’s Galileo HDX on Gulfstream G280s by early 2025, giving operators access to the latest high-speed in-flight internet solutions.

“The demand for reliable, high-speed in-flight connectivity is higher than ever,” said Skyservice president and CEO Benjamin Murray. “Our development of this STC for Gogo Galileo HDX is a direct response to meeting that demand with cutting-edge solutions.” There are about 240 of the popular super-midsize G280 in operation worldwide, the company said.

Gogo Business Aviation’s latest innovation, Gogo Galileo is designed to provide operators worldwide with global, high-speed, in-flight internet and low-latency performance for business aircraft from light jets and turboprops to the largest business jets. The compact HDX aims to leverage Eutelsat OneWeb’s enterprise-grade low-Earth-orbit (LEO) satellite network, which is designed for mobility to deliver low variability and consistent performance across all routes globally.

Mississauga, Ontario-headquartered Skyservice aims to get the G280 Gogo Galileo HDX STC validated by Transport Canada Civil Aviation (TCCA), the FAA, the European Union Aviation Safety Agency (EASA), the National Civil Aviation Agency of Brazil (ANAC) and the U.K. Civil Aviation Authority (CAA).

Operators can contact Skyservice (www.skyservice.com) to submit a purchase order for the Galileo HDX, which is designed to be an easy upgrade to any AVANCE system (AVANCE L3, L5, LX5, SCS). Installations are planned for 2025’s first quarter. A special promotional rebate of $25,000 is also available for a limited time to current Gogo customers operating a legacy air-to-ground system (ATG 1000, 2000, 4000, 5000) when installing AVANCE SCS and HDX, Skyservice said.

AvAir Broadens Lufthansa Technik Component Pact

AvAir has broadened its partnership with Lufthansa Technik Component Services, acquiring more than 1,600 overhauled wheels and brakes from the German MRO’s excess inventory.

Chandler, Ariz.-based AvAir’s inventory acquisition includes components for Bombardier CRJ700s and 900s, Embraer E190s and the complete range of Boeing and Airbus models, including the 787 and A350. AvAir said all parts are serviceable and come from Lufthansa Technik’s material pool and aircraft teardowns. Their transfer from Lufthansa Technik facilities in Germany to AvAir’s Chandler warehouse is expected to be complete by early February 2025.

The transferred material from this transaction is to come with dual or triple release certification (the FAA, EASA and/or the Civil Aviation Administration of China) from Lufthansa Technik and with a 12-month warranty, AvAir said. Most parts were maintained by Lufthansa Technik’s component maintenance, repair and overhaul organization.

“We are thrilled to expand our inventory with such a diverse range of wheels and brakes, enhancing our offering for our customers,” said AvAir president Brandon Wesson. “Our partnership with Lufthansa Technik has been invaluable, and we look forward to the new opportunities this acquisition will bring.”

The companies established their long-term aftermarket sales agreement in 2020, with AvAir acquiring more than 9,000 line-replaceable units from Lufthansa Technik’s global material pool. In 2022, AvAir expanded its inventory by purchasing 9,000 more aircraft components.

Lufthansa Technik is to receive a share of proceeds from resold components under a profit-share arrangement.

For more information about AvAir, visit AvAir.aero.

DHL Express Building New Maintenance Base

DHL Express in October began constructing a state-of-the-art facility and expanded aircraft apron in its global hub at the Cincinnati/Northern Kentucky International Airport (KCVG) to improve the express shipper’s ability to maintain its Boeing 737, 767 and 777 fleets.

The 305,000-square-foot (28,335-square-meter) facility in Covington, Ohio, will enable more efficient repairs, reducing aircraft downtime and improving service reliability to support timely customer deliveries, the company said. It is to include a hangar that accommodates two 777s or four 767s. The facility is also to have a ground service equipment staging area, underground foam containment, a loading dock and service entrance, backup generator capability, HAZMAT storage, a large water tank, offices and employee parking.

The expanded apron, covering 50 acres (20.2 hectares), will include eight new aircraft gates and three new maintenance gates.

That will allow DHL to accommodate more aircraft and handle a larger volume of shipments.

The $292-million facility is expected to be fully operational by January 2026.

DHL’s KCVG hub currently operates on 194 acres (78.5 hectares) with 67 aircraft parking gates and 6.4 million square feet (594,579 square meters) of ramp area. The heart of DHL Express’ Americas network, it handles 117 daily flights and a fleet of 64 aircraft and connects customers from more than 220 countries and territories worldwide to every corner of the U.S. KCVG is one of three DHL global superhubs, with the others in Hong Kong and Leipzig, Germany.

“Over the last several years, we have been enhancing our network capabilities with newer and more fuel-efficient aircraft,” said Rob Hyslop, EVP Global Aviation, DHL Express. “This new facility complements those efforts with additional space for more aircraft to be maintained at the same time.”

DHL expects to hire 300 more employees to support the new maintenance facility as part of a recently developed joint venture between DHL Express and Kalitta Air, a long-time DHL service partner. Kalitta Air and DHL will jointly oversee the critical aircraft maintenance activity at the new facility.