FL Technics is an integrated aircraft maintenance solutions provider, with offices across globe. The company’s expansion and growth over the last decade have been nothing short of phenomenal. It has been fascinating to watch FL Technics’ growth and change over the years, and it’s been amazing to document and to follow along. The company has hangars and shop facilities in most corners of the world, as well as an extensive network of line maintenance support stations across Europe, the Middle East, Asia Pacific and Canada. The company isn’t finished growing yet. It is about to open a brand new, tailor-made facility in the Dominican Republic to facilitate expansion in the Americas. CEO Zilvinas Lapinskas has been at the helm since 2013 and has overseen the amazing growth of the company.

As CEO of FL Technics, Lapinskas is responsible for the financial performance, including budgeting, capital allocation and profitability, while managing operations, risk and regulatory compliance. He says his goals as a leader include driving innovation and expansion and maintaining brand reputation are key priorities, along with fostering a strong company culture and employee engagement. He says he is focused on sustainable growth and operational excellence. Aviation Maintenance had a recent conversion with Lapinskas to hear about where the company is now, how they have thrived and what’s next for this global powerhouse MRO.

Aviation Maintenance: Give our readers an overview of your long list of capabilities.

Zilvinas Lapinskas: Let me start by saying that we are base maintenance providers, mainly for narrowbodies. We hold capabilities of Boeing 737 — Classic and NG — and we are about to get Maxes; then the Airbus A320 family; and we have just got Embraers — 170, 190. Before that, we had the Embraer 135 and 145. And, in our facility in Prestwick, Scotland, we support Boeing 787 and Airbus 330. That’s the only place where we provide maintenance to widebodies. As for the locations for base maintenance, mainly we are in Europe. Let’s start with Vilnius and Kaunas, Lithuania, Jakarta, and Bali Island, Indonesia, Prestwick in the UK.

Aviation Maintenance: What is your base maintenance expansion plan?

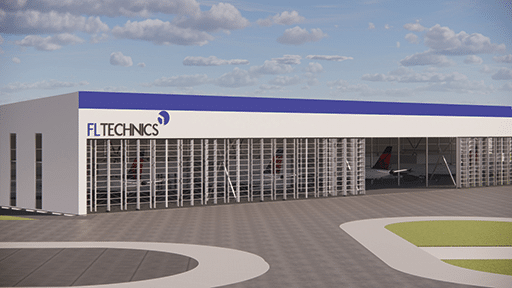

In October this year, we will open a facility in Punta Cana, Dominican Republic. In the Dominican Republic, we are building the facility for narrowbody aircraft base maintenance – — A320 family and Boeing 737s, NGs and Maxes.

Aviation Maintenance: FL Technics operates a network of line stations across Europe, Asia Pacific, North America and the Middle East. Tell us about your line maintenance work?

Lapinskas: We have roughly 100 line maintenance stations. Line maintenance stations in Canada where we acquired the company Wright International in 2020 was our entry into the North American aviation services market. In line maintenance, we provide maintenance to all the aircraft types: narrowbody and wide-body aircraft.

Aviation Maintenance: Who are some of your big line maintenance customers?

Lapinskas: Wizz Air, SAS and SAS Link and Turkish are big customers for us. Such airways as Qatar Airways, Etihad Airlines are line maintenance customers at our line maintenance stations in Europe. On the other side of the globe, in Canada line maintenance stations, we provide maintenance to such airlines as Iceland Air, Avianca, Egypt Air, Aero Mexico, Flair, Tap Airlines, Saudia Airlines.

Aviation Maintenance: Talk about FL Technics’ capabilities.

Lapinskas: We cover base and line maintenance, CAMO services (Continuous Airworthiness Management Organization) with more than 100 aircraft under CAMO. We have our own design and production organization, where we provide interior minor and major modifications. We design, print and apply livery decals. Recently, we expanded our scope and opened our own in-house sewing shop, approved under Part-21G.

The biggest part of our business is component trading. So, we buy narrow bodies like 320s and NGs and perform teardown of airframes. After the teardown, serviceable parts are released to the market and sold. It also provides us with our own stock. We have more than 500 customers all around the world. We have sales offices in Vilnius, Dubai, Thailand, Jakarta, Miami and so on. Latin America is not as well covered at the moment with spare parts trading, but it will be covered in the near future.

Another business stream at FL Technics is assets management. Assets such as engines, landings gear and airframes. We buy engines, and much like the airframes, we perform teardown and sell the parts. We also repair engines in our engine shop (or our partners’ shop) and sell engines. We have our own engine shop, a hospital repair engine shop in Kaunas, next door to our hangar where we repair and maintain the CFM56 engines: CFM-3, CFM-5, CFM-7.

Aviation Maintenance: What about wheels and brakes? Do you maintain wheels and brakes?

Lapinskas: Yes, now we come to wheels and brakes. We say that we are the number two provider of wheel and brakes service in the world. We have more than 600 aircraft under our contracts and programs. Our biggest customers are Tui, Norwegian, Wizz Air. We have dedicated wheels and brakes facilities in Hanover, Germany; in Budapest, Hungary, and opening a new facility in Bergamo, Italy. We also have a wheels and brakes shop in Vilnius, our base maintenance facility. It’s just the beginning. We have big ambitions and anticipate further growth of this business.

Aviation Maintenance: FL Technics also does logistics, correct?

Lapinskas: We also have a dedicated team for logistics. A few years ago, we decided to offer aerospace logistics services, as we deliver hundreds of parts each day for our customers. So, we offer our parts transportation know-how for third-party customers by providing the logistics [for them]. Not all logistics companies have an understanding of how aviation components, like engines, should be handled. We are planning to grow this business line as well.

Aviation Maintenance: There is also a training component to your business. Tell our readers about that.

Lapinskas: Yes, we have a very well-developed business of technical training. We provide technical training in more than 70 locations around the world. We have customers in Asia Pacific Central America, Africa, Europe, etc. Currently, we do not provide technical trainings in the United States because of the different regulations. We are an EASA Part-147 organization. More than 5,000-6,000 technicians get certifications from our technical training organization each year. In addition to technical training, we also offer online courses. And our strategy is very simple. We send our instructor to the customer’s place. I mean, if we have a customer somewhere in Central America, it doesn’t mean that this group of 25 people are coming to our hangar to do the training. It’s easier to send the instructor to their place instead of sending 25 guys to our place.

Aviation Maintenance: So, there has been a lot of expansion and growth into multiple areas during your tenure here.

Lapinskas: The revenue for 2024 was 400 million euros. When I joined the company at the end of 2013, the revenue was $80 million. So, during these 10 years, we grew five times, to 400 million. But we have to remember that we lost two years for COVID.

Aviation Maintenance: it is an amazing story. It’s been interesting to watch, and to report on over the years. Talk about some of the challenges that you’ve met as the company has grown.

Lapinskas: We have always been very active in the market with ambitious growth plans. When I joined the company, there was one hangar in Vilnius, a few line maintenance stations in Central Asia, and Vilnius. We started component trading business shortly after I joined. We also started expanding our line maintenance business. We built another hangar in Kaunas [Lithuania]. In parallel, we were looking at other regions for growth and aviation aftermarket in Asia-Pacific was growing, there was a demand for MRO services. So, we rented the hangar in Jakarta, Indonesia, in 2015, and we built the MRO facility there from scratch.

We’ve got long-term customers; we’ve got a strong presence there and have started looking into expansion. We started talking to different airports in Indonesia. We considered if they would like to build a hangar for us, and we are ready to utilize it for the next 20 years. Finally, we got an agreement with Bali International Airport. They built a hangar, which we officially opened in November 2024. Right after the opening, we received maintenance approval from Australian CAA. We’re looking forward to the customers from Australia, Due to a huge number of flights from Australia to Bali Island, we can offer our customers to fly to our facility for maintenance without a ferry flight. It’s a good competitive advantage.

Aviation Maintenance: There were some acquisitions at that point, correct?

Lapinskas: In 2020 we acquired company in Italy -Flash Line Maintenance for the line maintenance expansion. Our subsidiary Storm Aviation also expanded. and in 2021, we acquired the Chevron Aircraft Maintenance and Chevron Technical Services, a family business MRO in Prestwick and Manchester. So, we now have a group of companies in the UK. We are growing organically, and we are growing by acquisitions.

To develop a closer relationship with our customers, we have opened an office in Dubai, UAE. We have much better connectivity with Africa from our Dubai office, and now we have built a strong client pool from Africa. That business is growing 20% each year.

Aviation Maintenance: What about your line maintenance business?

Lapinskas: We acquired Wright International Company in Canada, which had five-line maintenance stations — it was the beginning of our business in North America. Wright International has line maintenance services up to ‘A’ level checks, A.O.G. support and training for airlines at Canada’s major international airports, including Toronto Pearson, Vancouver, Calgary, Montreal-Mirabel and Ottawa. Wright is a Transport Canada and EASA Approved Maintenance Organization (AMO) licensed to service most commercial aircraft types.

Aviation Maintenance: You make it sound easy.

Lapinskas: What I’m telling you sounds very simple. It was not so simple. It was very challenging. A lot of hard work and dedication and I say that for great success you need 95% hard work and 5% success to be where we are today. Some of the cases, for example wheels and brakes might seem easier than others. In three years, we became the second largest Wheels and brakes services provider in the world because we were in the right place at the right time. A previous provider decided to close their wheels and brake shop in Europe and the customers came into the market. That’s why we have Norwegian, Wizz Air and Tui in our client’s pool today. That was the beginning. [There was] strong and fast growth of that business. This is just the beginning.

Aviation Maintenance: It is very difficult to manage a business that exists all over the world. Some places are harder to get to than others. Talk about things like standardization and keeping the quality of your work the same throughout the company, even in these locations around the world.

Lapinskas: I can answer that. I’m quite a big fan of LEAN methodology. We have standard procedures, standard practices, and guidelines on how we provide services, especially in base maintenance. We have our own time calculation system. We created our own production system. We call it base system. We use it in all of our facilities. When we implemented that, we became competitive and attractive to customers from Western Europe – When I joined the company at the end of 2013, 90% of the revenue was from Russia and CIS. It was a challenge to do that full turnaround of the production system, change the mindset of people and so on. And then, of course, when we entered completely new markets like Asia Pacific, [lean] is their mentality.

You have to be very flexible with your understanding and with your expectations. You cannot expect the same approach from the people in Europe as from the people in Asia-Pacific or North America, Latin America. The cultures and mentality are different. Also, you have to understand the local mentality, how to organize the work, build trust with employees. That was a challenge. But aviation is a multicultural business. Every day you meet people from different parts of the world, but we are all united by the passion for aviation.

Aviation Maintenance: What are some of the milestones that you’re most proud of during your tenure as CEO?

Lapinskas: I would say the global expansion of the company would be one of the proudest milestones. MRO from Vilnius expanding to Jakarta, to the UK, Canada, Africa, Italy, Bangladesh, Thailand office, now moving to Punta Cana, we can say we are a global player. I’m really proud of my team. The bigger part of the team has been working with me for up to 11 years. We are not just colleagues. We are real partners.

Why have you chosen expansion in Punta Cana?

The new facility in Punta Cana represents a significant milestone in FL Technics’ expansion, bringing our aircraft repair and overhaul expertise closer to operators in the Americas. Customers from United States and Latin America can reach us easier. We can have a well-diversified business with quite an attractive cost base.

Aviation Maintenance: The project in Punta Cana, Dominican Republic sounds exciting. Can you tell our readers what stage this project is at?

The facility is nearing completion construction, we have already secured key specialists and are actively recruiting the remaining team. Additionally, the certification process with the Federal Aviation Administration (FAA) and Instituto Dominicano De Aviación Civil (IDAC) is currently underway.

Located in Punta Canta, the site will open in October 2025 and will allow us to provide heavy maintenance operations in the Americas through a 52,000-square-meter complex, delivering base maintenance for Airbus A320 and Boeing B737 family aircraft.

We will roll-out of the new state-of-the-art aviation maintenance hub in three strategic phases. Phase one of the project will introduce a 20,000-square-meter hangar, featuring 5 maintenance bays and an integrated series of support workshops with sheet metal, composite, paint, and interior capabilities. This October we start operations with five. 50% of the hangar facility’s construction has already been completed.

Phase two of the project will see the facility expand to 12 maintenance bays, positioning Punta Cana as a strategic MRO hub for airlines operating in the region. The third and final phase will grow the facility to 20 maintenance bays.

Aviation Maintenance: How many people do you expect to be employed there when hangar in Punta Cana opens?

Lapinskas: With five bays, there’re will be roughly 350 people. Initially, we’re planning to bring people over from oversees. And then, of course, our technical training department will help to train locals.

Aviation Maintenance: Any unforeseen issues with the construction?

Lapinskas: There is a rainy season in Punta Cana, and, of course, that influences the construction. But now everything is going smoothly, according to the plan. We have a supervisor who is over there all the time. In September the hangar is going to be ready for the audit and we’re opening it in October.

Aviation Maintenance: Talk about winning business and being better than your competitors.

Lapinskas: We have to fight for our customers every day, as we do not have any guaranteed contracts from the airlines.

We are speaking about a labor-intensive business. Eighty percent of the cost is labor. And if your people are not working effectively, you will not earn any profit and you will not be competitive in the market.

Aviation Maintenance: And LEAN methodology has been a key part of that?

Lapinskas: Yes. We must fight for the customers every day, so it means that we have to be flexible, we must have a very good approach to the customers, and we have to be very, very efficient. So lean methodology, this way of thinking, how we can do better, how to remove all the waste from our processes — it helped us a lot.

Aviation Maintenance: Talk about being a part of Avia Solutions Group and the support that they give you and how that works.

Lapinskas: We have a strong board of professionals in aviation. I’m also a member of the board of Avia Solutions Group. We have good discussions, and we have a very serious guy with a vision, our chairman and founder of Avia Solution Group Gediminas Žiemelis, leading us. We are part of the management team are our shareholders, so we are partners sitting in the same boat and moving in the same direction, simply speaking. And, of course, the expertise from the airlines in the group and the support, sharing contacts, sharing the experience, sharing the knowledge — that’s good.

Aviation Maintenance: Where else do you see growth?

Lapinskas: We have prepared the plan for FL Techniques group goals. We call it Plan 2030. As I mentioned before, 2024, it was e400 million euros revenue. The plan for 2030 is one billion. That means we want to grow two and a half times by 2030. This is not just a vision. Each business line has its own business plan with all the steps calculated and what we must do, what we must reach, to get there in 2030. We are speaking about new acquisitions. We are speaking about new facilities. We are speaking about new investments into assets, into spare part business, into capabilities and so on and so forth. All these numbers are prepared now, and we will be working on reaching those goals. There’s a clear plan with all the financial figures, 2030, and we are moving in that direction. For the last seven, eight years, we have been growing by 10 to 20% each year. [We hope to keep] the same speed. Of course, you know, it’s a plan. Sometimes you have to adjust the plan or some circumstances which you cannot influence occur. But this is the vision, this is the direction that was presented to the board, the board approved it, and we are moving now in that direction. Our employees also believe in that vision, and they follow that vision.