Efficiently managing aircraft parts and inventory aids seamless maintenance operations.

Effective aviation spare parts inventory management is fundamental to maintaining operational readiness in any MRO or fleet environment. Without precise visibility into parts availability, location, condition and trace documentation, organizations face avoidable delays, excess cost and higher aircraft on ground (AOG) risk.

Aircraft spare parts inventory management software benefits operational precision. “Technicians know exactly what’s available, schedulers can plan with confidence and maintenance leaders gain tighter control over cost, service levels and turnaround times,” says Kris Volrath, chief product officer at Veryon, San Francisco. “By reducing surprises and eliminating manual workarounds, organizations can avoid preventable AOG events and deliver a more predictable, high-performance maintenance operation.”

Gerry Merar, president of AvPro Software/Decision Software Systems Inc., West Palm Beach, Florida, agrees that aircraft parts and supplies management software is “essential to running any type of aircraft maintenance facility efficiently. Whether it’s serialized/lot-tracked parts or consumable supplies, there are so many items that it would be almost impossible to track manually.” Merar explains a full inventory application will benefit an organization by tracking:

• Purchases of parts and consumable supplies (purchase orders)

• Parts sent out for repair, overhaul, calibration or any other maintenance service (repair orders)

• Receiving items into stock, managing packing slips and reconciling vendor invoices to receiving batch reports

• Recording parts that are rejected and/or returned to vendors

• Reporting on-hand inventory stock and in/out activity

• Financial reporting on inventory valuation and costing

• Providing a physical count check system to prevent theft and loss due to item expirations

• Barcode labeling

• Helping to organize your stockrooms with bin location management

• Providing traceability for parts sources and parts issued to aircraft and work orders/technicians

Inventory and materials planning is the airline function with the ultimate responsibility for the on-time supply of material and the associated costs. Inventory planning provides the framework for all other supply-chain activities to operate efficiently and coherently. “Given the complexity, scale and uncertainty of aviation maintenance, inventory planning is a strategic necessity,” says Micheál Armstrong, CEO, Armac Systems, Dublin, Ireland. “Effective planning can only be accomplished with the support of well-defined processes and systems specifically adapted to the requirements of airlines and MROs. The role of inventory planning is more than calculating stock levels. Inventory planning determines how parts will be supplied and the priority of activities. It is distinct from execution functions such as purchasing, logistics and repair management, which deliver to the plan, just as line or base maintenance engineers work to the maintenance plan. Given the uncertainty and scale of MRO and airline maintenance, inventory planning is an indispensable strategic and tactical function.”

Evolution

Aviation inventory planning traditionally relied on expert users and spreadsheets. Armstrong explains with the development of modern software tools leveraging AI/ML, grid computing has revolutionized how material planning is accomplished. “As data science is becoming more established, acceptance of data-led decision-making has increased, resulting in greater adoption and consequential honing of the solution landscape.”

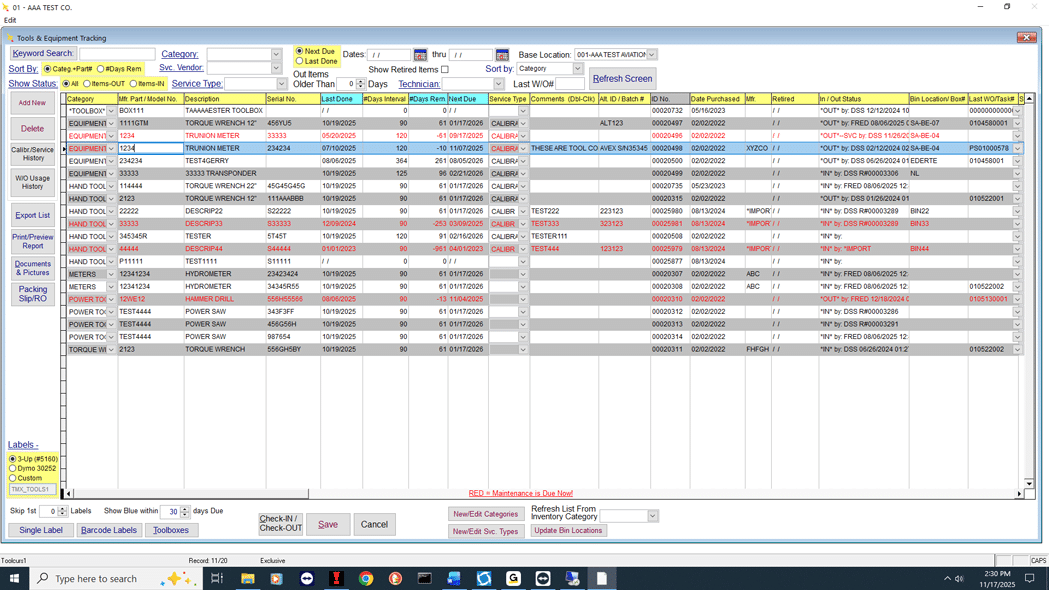

Merar explains inventory management software has evolved so it is easier to use and more affordable for smaller facilities. “Having it as a separate standalone module, such as AvPro’s Inventory Module, makes it less intrusive so having it won’t interfere with other applications vital to the operations of the company.”

A few years ago, most inventory systems functioned as little more than digital ledgers. Valrath explains, “They stored part numbers, bin locations and quantities, but they couldn’t validate accuracy, anticipate demand or reflect the operational realities happening on the hangar floor. Data quickly went stale, and teams relied heavily on tribal knowledge or spreadsheets to bridge the gaps.”

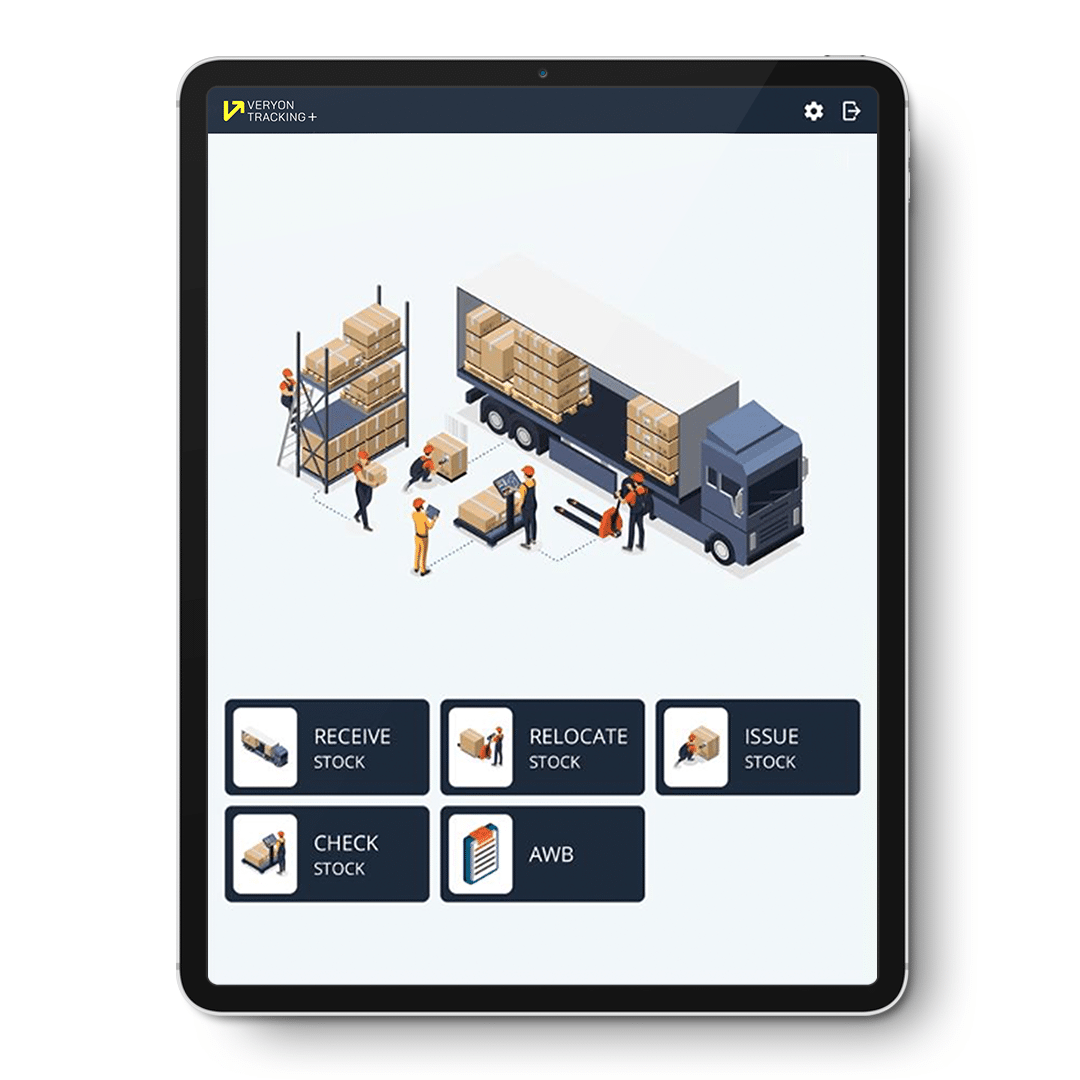

Today, modern solutions, such as Veryon Tracking+ paired with the Veryon Stock mobile app, deliver improved operational intelligence. Instead of simply recording information, they capture real-time activity directly from the stockroom; receipts, issues, relocations, counts and Air Waybill processing all update the system instantly. This creates a live, continuous picture of inventory health rather than a snapshot.

Inventory is no longer managed in isolation. Maintenance plans, component usage history, compliance requirements, and upcoming scheduled tasks are all connected. Valrath says teams can see which parts are committed, which components are cycling toward removal, and what demand is on the horizon — giving them a significantly more accurate basis for planning. “The result is a shift from reactive to proactive. Instead of hoping the data is correct or making decisions based on assumptions, material managers operate with clear, reliable insight tied directly to clear behavior. It’s a far more strategic, proactive approach to inventory management.”

Advances and Updates

Some of the biggest advances in aviation spare parts inventory management center around mobility, automation and predictive intelligence. Mobile tools like the app have changed how teams work. Counts, receipts, moves and AWBs happen right where the work happens, which eliminates lag and keeps data accurate.

Another major shift is the deeper integration between inventory control, maintenance planning and operational scheduling. “Veryon Tracking+ now allows teams to see exactly which parts are available, what’s already committed to work orders and what upcoming tasks will require,” Volrath says. “With real-time synchronization between stock movements and maintenance demand, operators can plan with greater certainty and avoid avoidable shortages or rework.”

Merar explains another advancement is that barcoding and RFID technologies, “help to greatly reduce data entry errors and speed up the process of recording in/out activity of inventory items. Robust reporting options make managing on-hand stock and costing of items much more efficient.”

Applying the latest artificial intelligence, machine learning, advanced mathematical models, and cloud computing architecture, Armac’s RIOsys software enables airlines and MROs to leverage their data to optimize inventory planning. Predictive maintenance is an emerging tool that can support this objective; it’s a data-driven strategy that uses real-time data, advanced analytics and machine learning to anticipate failures.

“Its positive supply chain consequence is that it converts some short-term probabilistic demand into deterministic, planned events,” Armstrong says. “Predictive maintenance offers aviation operators significant benefits by reducing unscheduled downtime, when implemented as part of an integrated decision-making process. To be effective, predictive maintenance solutions must be incorporated into the wider processes and systems of the operation. In response to a predictive maintenance alert, inventory planning must assess supply chain options to optimize the supply. This can be integrated into an inventory optimization solution as a new demand signal to further optimize the supply chain response. Armac is working with our customers to integrate the predictive demand signal, with other forecast demand types, into our holistic optimization of inventory planning.”

What’s Unique about Aviation?

What’s unique to the aviation industry in regards to spare parts inventory management? The level of traceability required is very high. Every serialized part must have a complete history, documentation and compliance proof. If the trace isn’t perfect, the part can’t be used.

Merar explains, “Having the traceability factor from source to end use on an aircraft is essential to track problems that can occur and prevent issues before they happen. For example, being able to track serial and manufacturer lot numbers is very important if there is a recall or some problem has been identified by the manufacturer. When there is a failure the root cause must be identified so future events are prevented.”

Valrath cautions the cost of a missing aircraft part is immediate. “If you don’t have what you need, you can ground an aircraft. Most industries don’t feel that kind of pressure from inventory.” Also, Valrath explains that fleets vary widely. “[There are] older aircraft, newer aircraft, different operating environments and different histories. Teams can now use software to understand how those differences affect part usage, enabling smarter stock management.”

Armstrong believes that MRO or airline maintenance differs from the classic manufacturing model in its uncertainty of demand and the bi-directional flow of material. Even if tasks or work packages are scheduled, “We cannot know with certainty which components on which aircraft will need replacement, or parts will be required. Findings related material demand on a scheduled check represents significantly highest proportion of overall demand. Because many components are repairable and reused, standard replenishment models like ROL or MRP don’t apply. Planners must prioritize repairs and maintain sufficient serviceable parts in rotation within the repair and reuse cycle to meet demand.”

In the aviation industry, many of the inventory planning and procurement systems and processes have been developed based on standard manufacturing models. Armstrong cautions these standard systems are unsuitable for the idiosyncratic nature of aviation. “This mismatch has resulted in off-system workarounds, a lack of standardization, sub-optimal processes, and a high dependency on experts, with poor controls.”

Often, because MRO IT systems are unable to adapt to the nuances of the industry, the stock picture provided by the system does not reflect true stock levels; airlines frequently have the automatic reorder level functionality switched off in their MRO IT System as a result. It is important that the inventory optimization system understands the supply model and reflects the stock picture correctly, to ensure that the correct recommendations are generated and in the correct priority. Smart algorithms are required, and are embodied in the RIOsys software. However, to maximize value, it is necessary to ensure that the model applied to the input data accurately reflects the operation. RIOsys has been designed, and is proven, to address the maintenance operating model of airlines from both a demand and supply perspective.

Learning Inventory Management

Inventory planning is complex and dynamic. It requires an expert system to take millions of changing variables and holistically optimize decision-making. However, modern aviation inventory tools are more intuitive and far easier to learn than legacy systems. The Veryon Stock app functions like a familiar mobile application, which helps new users come up to speed quickly. “Scanning a barcode, issuing a part, taking a photo for trace … it all feels intuitive,” Valrath says. “Veryon Tracking+ also follows the same logic as real maintenance and stockroom workflows. There’s no hunting around the system for what to do next. And because mobile and desktop follow the same structure, users pick it up fast. Role-based training and guided prompts go a long way, too. People see exactly the steps they need without being overwhelmed.”

AvPro has a standard interface which allows novice computer users to learn it. Merar believes this makes it faster and streamlined for the advanced users. “Efficient screen layouts and clearly marked clickable buttons enable a short learning curve and will provide on-screen help tips for functions that are not used frequently.”

Armac’s RIOsys inventory optimization takes all of the complexity and presents the planner, for material within their scope of responsibility a set of prioritized actions, with all of the salient supporting information to allow the planner to confidently execute the action.

Ultimately, the aircraft industry is learning that parts management is now a core driver of reliability — not just an administrative function. When inventory data ties directly into maintenance history, component usage and upcoming scheduled work, teams gain a far more accurate view of future demand. That means fewer shortages, less overstock, and better alignment between materials and maintenance. Smarter parts management keeps aircraft available, keeps operations moving and keeps costs under control. It’s becoming one of the strongest levers operators have to improve reliability and efficiency.