A critical enabler of aviation, composite repair ensures continued airworthiness and aircraft reliability.

Composite materials offer the aerospace industry many benefits because they are stronger, lighter and more durable than metals like aluminum for many components and applications. These materials’ repair is a vital part of maintaining today’s aircraft. With their increasing use in airframes, control surfaces, nacelles and interiors, the ability to repair rather than replace them helps operators reduce costs, minimize downtime and extend the service life of critical structures, while ensuring safety and regulatory compliance.

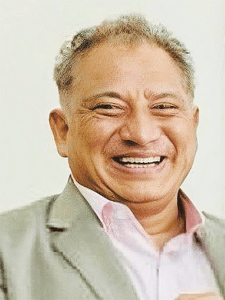

“Composite repair is the unsung backbone of the aviation industry,” says Nick McDonald, vice president and general manager of Evans Composites, Mansfield, Texas. “As fleets age and shift increasingly toward composite materials, its role has become indispensable. At its core, composite repair ensures that the external components of every aircraft remain safe, reliable and airworthy.”

Sunny Mirchandani, general manager at HAECO Composite Services, Greensboro, North Carolina, explains that, “Composite materials now account for more than half of the structure in advanced aircraft such as the Boeing 787 and Airbus A350 …making it a critical enabler of modern aviation. Effective repair solutions are essential not only to restore structural integrity after damage but also to ensure the continued airworthiness and reliability of these aircraft throughout their life cycle. By maintaining safety standards while minimizing downtime and cost, composite repair supports both operational efficiency and the long-term sustainability of the aerospace industry.”

Repair Techniques

While there are different composite repair procedures, each has the basic function of restoring a part’s structural performance, aerodynamic smoothness and safety certification.

Composite cosmetic repairs are used when the integrity of a part is not affected by the damage. “Cosmetic repairs address surface scratches, paint or erosion without affecting structural integrity,” says Nick Weber, regional vice president of Middle East, EXECUJET MRO Services, Johannesburg, South Africa.

Scarf repairs remove damaged material and tapers the edges to bond in new composite layers. “[This] provides structural integrity and restores aerodynamic shape,” says Kyle Shoemaker, director of marketing at Coltala Aerospace, Mansfield, Texas. “Bolted/bonded patch repairs add a composite or metallic patch over the damaged area using fasteners or adhesive. [This] provides strength quickly but may not be as aerodynamic.”

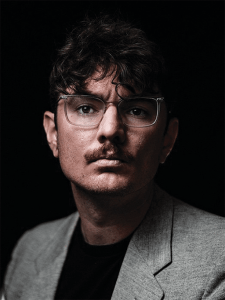

Wet layup repair is a practical solution for less structurally demanding applications or field-level repairs. “Resin injections fill damaged areas with resin under pressure, or a flush plug patch by removing the damaged section and filling the hole with adhesive material,” says François Fermaut, aerostructures operations director at Vallair. “This also includes some temporary wet layup repairs performed on the aircraft through the installation of composite layers impregnated with resin and cured under a vacuum bag with a hot bonding system.”

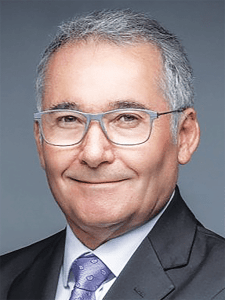

“Wet layup involves saturating dry fiber material, typically fiberglass or carbon fiber, with resin, layering it to restore strength and then curing it under controlled conditions,” adds Patrick Meyer, senior vice president and general manager at STS Aviation Services, Shannon, Ireland.

In contrast to wet layup repair, pre-preg repairs use fabric pre-impregnated with resin, requiring controlled temperature and pressure — typically through an autoclave or heat blanket — to cure. “This method offers greater consistency and strength, making it the preferred choice for load-bearing or primary structures,” Mirchandani says. “While both techniques aim to restore structural performance and airworthiness, the selection depends on the criticality of the component, repair environment and operational requirements.”

“Core replacement focuses on damaged honeycomb or foam structures, which is crushed or moisture-contaminated,” Meyer says. “The damaged core is removed and replaced before being sealed with new plies. Vacuum bagging is often used with wet layup and core replacement techniques to eliminate air pockets and excess resin, while controlled heat application ensures uniform curing and a stronger bond. The end goal is always the same: restore the original strength, rigidity and aerodynamic profile of the component.”

Difficult to Repair

Some composites are more difficult to repair than others. And, any structures with complex geometries or limited access will be a challenging repair. This includes, “Structures that have integrated (molded) stiffeners such as stringers in composite wing skin and fuselage designs,” says Louis C. Dorworth, direct services manager at Abaris Training Resources Inc., Sparks, Nevada. “These are susceptible to high energy, wide area, blunt impact (HEWABI) damage from ground vehicles and other overloading situations, and are hard to detect, inspect and repair. On a smaller scale, parts and structures with compound contoured, aerodynamic requirements can be challenging and often require localized tooling to maintain surfaces.”

Meyer explains that large structural components such as fuselage sections, wing skins or internal load-bearing members are particularly challenging because they cannot always be removed from the aircraft. “In those cases, repairs must be performed in situ, often in less-than-ideal environments compared to a clean workshop. This creates added challenges for quality control, health and safety, and environmental conditions like dust, temperature and humidity, all of which directly affect repair outcomes.”

At Vallair, Fermaut has witnessed three problematic composite repair scenarios:

• The position of the damage. When Vallair technicians need to repair the lower skin of the fly control, it’s not always evident how to properly install the repair patch and the vacuum bag due to gravity.

• The shape of the part to be repaired. If the surface is not flat, the part needs to be removed and Vallair needs to perform some local tooling to support the material during curing process mainly for the belly fairing and radomes.

• The nacelle parts — the composite is exposed to lots of stress, environmental or heat damage. For those units Vallair teams normally need to remove them from the aircraft and send to the shop to perform the defect analyses and repair to the correct condition.

Weber agrees that composite repairs are more challenging on curved or complex geometries like winglets, nacelles and radomes because achieving correct ply orientation, surface preparation and vacuum bagging can be technically demanding. “Large, bonded structures, such as fuselage skins, can also be difficult due to access, repair size and the need for precise curing conditions.”

Composite Repair Evolution

In the last five years, Fermaut says Vallair has increased non-destructive testing (NDT) during composite repairs, at different stages including initial inspection and/or final check. Even if they still use visual and TAP test methods to find disbanding in a sandwich structure, the use of thermographic or ultrasonic inspection is now a key factor. “This process gives us a clear understanding of the condition of the part and we can perform a clear mapping of the damage. In the MRO repair environment, Vallair can see improvements at all stages of a repair. During inspection, advanced NDT methods produce a correct mapping of the damage. During the repair itself new scarfing tools ensure repeatable and accurate repair geometries. During the curing system portable hot bonding systems [have improved]. And there has been improvement of the repair material itself: adhesive and resin.”

Composite repair sophistication has advanced significantly via artificial intelligence, machine learning and advanced software tools. Collectively, these technologies are slowly transforming composite repair from a highly manual craft into a more data-driven, precise and predictive discipline, ultimately improving safety, efficiency and sustainability in aviation maintenance.

“At its core, AI involves creating algorithms and models that can analyze data, identify patterns and make decisions based on that analysis,” Mirchandani says. “Without quality data, AI models are ineffective. AI adoption for composite repairs would require an AI database of repairs. For this to happen, many MROs, operators and OEMs would need to foster collaboration and promote transparency to contribute repair-data as a source for AI database. Composite repairs are a special skill and require process, materials and tools that are often of competitive advantage and an IP of the organization. There has been adoption of AI and machine learning (ML) and NDT where AI can identify and characterize damage (e.g., delamination, impact cracks) far more consistently than the human eye, thus reducing inspection time and eliminating technician subjectivity.”

ML algorithms can analyze large datasets from previous repairs and inspections, helping refine repair strategies and forecast material behavior. It supports continuous improvement by studying thousands of repair outcomes, refining processes and recommending more efficient repair schemes.

McDonald has witnessed the development of complex composite 3-D printing of aircraft components. He says it allows for the production of hard-to-find components at cheaper prices and in some cases higher durability. Also, “A major improvement in our shop is the use of a new cloud-based ERP allowing our technicians to have their data with them when they need it and not having to waste time returning to a workstation.”

“Advances in NDI methods and equipment continue to make inspection easier and more precise,” Dorworth says. “A technician can do the inspection on the part, on the aircraft, and consult in real time virtually with an offsite ASNT Level III engineer to best understand the damage assessment prior to and after damage removal and repair.”

damage, new scarfing tools ensure repeatable and accurate repair geometries and portable hot bonding systems have improved,

according to Vallair’s Francois Fermaut. Abaris image.

New technologies such as Smart Susceptor heat systems are finding their way into procedures. This equipment plays an active role in heat distribution over the repair area by reducing heat to hotter areas while continuing to heat cooler areas. Dorworth says it helps compensate for underlying heatsinks such as frames and stringers. “Other innovations such as using double vacuum debulk (DVD) processing for near autoclave quality patches to embedded heat sensors, surface-tolerant repair resins and other emerging technologies continue to enhance aviation composite repairs moving forward.”

Into the Cloud

Cloud-based and internal digital platforms, along with hand-held tablets or cell phones allow the technician/mechanic direct access to instructions, drawings, specifications and serialized record-keeping programs where step-by-step photo documentation can be stored. Weber explains that because of cloud testing, remote monitoring, and sharing of repair and curing data allows OEMs and operators to verify repair compliance in real time, enhancing traceability and quality assurance.

Digital transformation is indeed reshaping aviation repair and testing by making maintenance more predictive, data-driven and connected. Cloud-based platforms now store repair records, inspection results and historical data, enabling maintenance teams to access information globally in real time. “Combined with digital twin technology, operators can simulate the performance of components under various conditions, track degradation and anticipate failures before they occur,” Mirchandani says. “This supports predictive maintenance, where algorithms analyze fleet-wide trends to forecast repair needs, reduce unscheduled downtime and optimize maintenance planning. Ultimately, digital transformation enhances reliability, efficiency and safety while lowering lifecycle costs.”

“Composite repairs are not ‘difficult’ but they require the technician to follow all the processes without deviation, precise layering, bonding, curing and inspection,” Fermaut says. “A single mistake can compromise the entire structure. If the process is properly followed the repair can meet or exceed the strength of the original structure. Most composite repairs are invisible when completed and covered by the paint scheme of the aircraft. A proper follow-up of those repairs and a complete record needs to be kept by the CAMO to warranty the airworthiness of the aircraft.”

A Core Competency

Composite structure repair has moved to the forefront of aviation safety and reliability. It is not simply a maintenance task — it is a highly specialized discipline that combines materials science, precision engineering and advanced technologies to ensure structural integrity. It requires a unique combination of technical knowledge, precision and environmental control. Meyer believes that unlike traditional metalwork, mistakes in composite repair can compromise the structure in ways that are difficult to detect until much later. “That is why investment in training, tools and procedures is so critical. As more aircraft move to composite structures, the industry must continue to raise awareness that composite repair is a core competency, not an afterthought.”

Acknowledging that composite repair is indeed an essential core competency for modern MROs and no longer a niche capability, Weber stresses that with composite content in new-generation aircraft continuing to rise, “Operators should ensure they partner with MROs that have the facilities, OEM approvals and skilled technicians to handle both minor and complex composite repairs efficiently and safely.”