In an industry where cutting-edge airframes and advanced engines grab the public’s attention, the actual tools that MROs use to keep these items in service rarely get much attention, if any at all.

But make no mistake — without high quality hand tools, equipment testers and durable lightweight ladders, no MRO shop would be able to maintain, repair, and overhaul any of these high-tech items. To shed light on these vital assets, Aviation Maintenance magazine is examining three leading suppliers — Sonic USA, Druck, and LockNClimb — to learn more about their products, including the new tools they are bringing to the MRO market.

Three Trusted Tool Suppliers

When it comes to doing aircraft and engine repairs, Sonic USA (sonictoolsusa.com) naturally comes to mind. Sonic USA provides high-quality hand tools, toolboxes, and premium storage solutions to the aviation, space and automotive sectors. Founded in 2015, Sonic USA is the North American subsidiary of the Netherlands-based Sonic Group, a global specialist in the development, marketing, and distribution of professional hand tools and storage solution systems since 2004.

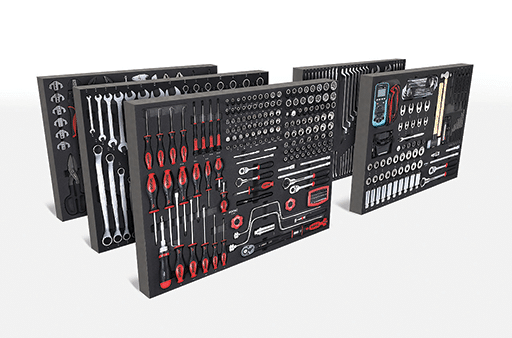

“Our aviation toolsets generally come in three versions with customizable foam inserts and serialized tool ID laser etching: basic (145 pieces), intermediate (263 pieces), and advanced (454 pieces),” said Sonic USA CEO Colby McConnell. “We most recently announced a TSA-approved mobile case that can hold either the beginner set, or our latest MRO offering, the intermediate mobile case set, respectively. We also provide a Sonic Next S12 XD storage system with eight drawers.”

has 145 pieces.

Durability is a top priority for Sonic USA. “We want to ensure our tools are built to last a lifetime,” McConnell said. “This is why Sonic USA stands behind every Sonic tool we make via the hassle-free lifetime warranty program that is the best in the tool industry. Our online warranty process takes just a few minutes to submit and replacement tools are processed within 24 hours. They are then shipped out from our warehouse in Auburn, Alabama.”

has 263 pieces.

Of course, one major reason that mechanics lose access to their most-prized tools is not because they break, but rather because they go missing. This is why Sonic USA offers its aviation customers the “No Lost Tools” Guarantee, which the company announced earlier this year. “Sonic will replace up to $250 in hand tools on any of Sonic’s preconfigured aviation complete toolkits in the Sonic Foam System (SFS),” said McConnell. “The No Lost Tools Guarantee applies for one calendar year after purchase, or from the toolkit ship date. Customers can file a claim through sonictoolsusa.com and then each claim will be processed within 24 hours whereby Sonic will then ship the replacement tool.”

The second trusted tool supplier that spoke to Aviation Maintenance for this article is Druck (www.bakerhughes.com/druck). Starting as a small business in Leicester, U.K., in 1972, Druck (a Baker Hughes business) has grown into a global pressure measurement company specializing in high-quality, high-accuracy silicon-based pressure sensors and calibration instrumentation for various markets, including aviation.

“For the MRO sector, Druck provides essential tools such as air data test sets, pitot static leak testers, handpumps, and after-market pressure sensors,” said Chris Roberts, the company’s product leader for test and calibration. “Producing more than 400,000 sensors annually, and with some 4,000 customers, Druck’s pressure measurement technology provides advanced levels of accuracy, reliability and stability, enabling customers to enhance safety performance and drive efficiencies and productivity.”

According to Roberts, “Druck’s expertise extends across the aerospace sector; their Aerospace Flight qualified pressure sensors division has served the aviation industry for more than 45 years, supplying over 700,000 sensors. This means 80% of commercial and several military aircraft fly with Druck sensors on board,” he said. “Beyond flight-qualified sensors, Druck also offers pitot static testers (ADTS) for precise testing and calibration of aircraft airspeed and pitot static systems, alongside a range of ground test pressure sensors and multi-function calibrators.”

Our third trusted toolmaker is LockNClimb, LLC (https://locknclimb.com), whose products make aircraft and engine servicing safer, faster and easier. “LockNClimb, LLC designs and manufactures ergonomic safety ladders for the aviation industry used in MRO facilities around the world,” said Banning Lary, the company’s communications director. “These ladders have been engineered to meet all applicable OSHA and ANSI standards and are proven to prevent costly accidents and injuries to line and hangar maintenance technicians. They provide a stable means to access many hard-to-reach maintenance areas on most big commercial and corporate jets. LockNClimb ladders’ durability is unmatched: after five years of continuous daily service in the demanding MRO environment, their repair costs remain at only 1/10 of 1%.”

LockNClimb’s product lineup includes safety ladders customized to serve all Airbus and Boeing aircraft along with all corporate and private jets. This company also can custom design and build safety ladders for any specific purpose or industry need. All of LockNClimb’s ladders are manufactured in the USA, which is useful information in this time of tariffs.

New Tools for MROs

Savvy MRO technicians and engineers are always on the lookout for new tools to help them do their work better and easier. Aviation Maintenance asked the three trusted suppliers in this article what new items they have to offer to the MRO market. This is what they told us.

In April 2025, Sonic USA released its new 263-piece Intermediate Aviation Toolset with Mobile Case, a mobile toolset comprising sockets, wrenches, pliers, punchers, and other tools all backed by Sonic’s hassle-free lifetime warranty. The tools are conveniently organized into one TSA-approved, hard-shell case with multiple handles and wheels.

“The complete Intermediate Aviation Toolkit (IAT) weighs less than 100 pounds, ideal for the aviation technician on the go,” McConnell said. “This new intermediate set is designed for aviation technicians who are, or are working towards becoming, airframe and powerplant (A&P) technicians. The intermediate toolset is also the perfect solution for hassle-free travel, yet robust enough to tackle most aviation repair and service jobs.”

Inside the IAT case, the company’s custom Sonic Foam System (SFS) keeps everything in its proper place even during the roughest of transports. (There’s no hassle that is more irritating to an MRO technician than opening their toolbox, only to discover everything inside is in a heap.) “When the toolset is in motion, technicians don’t need to worry about tools becoming jumbled and falling out of place,” said McConnell. “The two-toned chemical-resistant foam interior also maximizes storage space while keeping tools organized during the job.”

On the outside, a metal reinforced padlock hole enables technicians to completely secure all of the IAT’s compartments with one single lock, as desired. To further aid organization and prevent cross-contamination with other toolsets, serialized tool ID laser etching comes standard on each tool. Custom etching is available at an additional cost.

So, what does the aviation maintenance industry think of Sonic’s new product? “We first announced the 263-piece Intermediate Aviation Toolset with Mobile Case at the MRO Americas Show in April, and the initial response has been tremendous,” McConnell replied. “We feel we’ve found the right balance of providing the tools a technician might need for most service and repair jobs, but in a ruggedized yet lightweight TSA-approved casing that enables technicians to easily maneuver the tools wherever they need to go. Furthermore, the case is designed in such a way that it enables full access to the entire toolset at once without tipping over. And there’s still room for additional tools. We’re excited to offer such a comprehensive yet portable option for technicians who must frequently travel. It’s a must for ‘fly-away techs’.”

Meanwhile, Druck has recently introduced its DPl610E-Aero, which is a low-cost yet flexible portable calibrator for precision leak testing of aircraft pitot static systems. “During aircraft maintenance, when any work is undertaken on the pitot static system of an aircraft, a leak check must be completed to verify integrity,” said Roberts. “Any leaks in the avionics system will cause pressure changes resulting in false airspeed or altitude readings. Maintaining accurate airspeed and altitude is a vital safety parameter for aircraft operations. If an aircraft’s airspeed or altitude reads incorrectly due to pressure leaks, in-flight calculations become inaccurate. Leak testing is therefore a vital part of MRO procedures, meaning the integrity of the equipment cannot be overlooked. Using accurate and reliable equipment is a necessity.”

Worth noting: While pitot static testers can perform leak tests during full maintenance processes, aviation technicians often require a quick leak test for low level, go/no-go testing. Unfortunately, the often-cumbersome pitot static testers, whilst more than capable of performing this test, are usually not portable enough to do such quick tests quickly due to their size and weight. As well, pitot static testers are also very often tied up performing more complex scheduled maintenance tasks when a quick leak test is required. “This creates a gap in the arsenal of avionics technicians for a low-cost, portable precision leak tester,” Roberts said. “Hence the reason for the recent launch of our DPI610E-Aero portable leak tester.”

Now Druck has a history of producing quality pitot static leak testers. In fact, “the legacy DPI610A has been a staple of MRO service providers’ equipment for decades,” said Roberts. “But given this tester’s aging technology and limited user interface functionality, we at Druck decided the time was right for an upgraded leak tester, the DPI610E-Aero. It augments the most-loved features of its predecessor, combined with the latest pressure sensor technology.”

As for the MRO market’s response to the Druck DPI610E Aero? “Customers value the portability, reliability and long battery life resulting in less downtime,” he said. “It also means customers do not have to tie up a pitot static test system for a simple process. This time saving directly influences operational efficiencies, in terms of calibrations completed and aircraft leak tests. The DPI610E-Aero’s cost-effective price point is also a benefit to the customer. This is why, since launching the DPI610E in 2024, we’ve experienced high demand for this tester. Indeed, it is already benefiting many of our customers in Europe, Asia, Americas and the Middle East.”

LockNClimb’s newest products include a 3-foot platform ladder with fold down tool tray (3LNCB737WWPLT) designed and built for aircraft mechanics who needed a simple sturdy ladder to access the wheel wells and landing gear of Boeing 737 and Embraer aircraft.

According to Lary, a similar request was made by mechanics who wanted a single ladder they could use to access a dozen maintenance points around the exterior of the Airbus 320 series aircraft — and thus the 51LNCWWPLAT was born. This 51-inch high platform ladder features an OSHA 1AA Special Purpose ladder ANSI tested to hold 375 lbs. It allows technicians to quickly roll around an aircraft to service avionics, hydraulic, oxygen, E&E ports and many others. When the company is designing new ladders, “maintenance technicians, supervisors and safety managers are consulted during the research and design phase of each ladder,” said Lary. “It is not unusual for prototypes of new ladders to be brought back to the hangar and flight line half a dozen times for testing and development until they perfectly match aircraft profiles with technician working comfort. When we do bring the prototypes to market after being refined into finished products, mechanics and management alike praise our ladders for making work faster, safer and easier. This increases morale and productivity, thereby decreasing aircraft downtime.”

What’s Coming Next

As we have seen, Sonic USA, Druck, and LockNClimb are doing their best to bring advanced tools to the aviation maintenance sector. This leaves one last question to be answered: What’s coming next?

“Sonic USA remains focused on providing complete tool solutions that improve efficiency and asset management, along with FOD (foreign object debris) mitigation,” replied McConnell. “Sonic provides solutions to assist in FOD mitigation by implementing our organization system that optimizes tool control and inventory control system, allowing technicians to ensure every tool is back in place. We also want to ensure we provide complete hand tool solutions, including tools, toolboxes, and cabinets tailored for the aviation industry, eliminating the need to wait for a tool truck. For these reasons and more, international airlines ranging from United Airlines to Alaska Airlines, to regional players such as Piedmont Airlines rely on Sonic tools every day.”

Druck’s future plans rely on “harnessing our culture of innovation,” Roberts said. “At Druck we’re always looking to push the boundaries of innovation and reinforce our market leading position with new technologies. While our product launch plan is a closely guarded secret for commercial reasons, I can tell you that across aviation MRO we are looking to build a more systems-based offering with integration across the range, from asset management and calibration software to third-party instruments to drive operational efficiencies and deliver productivity gains. So, watch this space!”

“LockNClimb is continually engaged in developing new and better ladders to match the working needs of technicians with new and improved aircraft,” concluded Lary. “These include the 10- and 12-foot cowl pylon ladders that allow technicians to quickly access maintenance panels on the top of the wing pylon area of Airbus and Boeing aircraft. Our complete line of advanced A-frame ladders is preferred by many mechanics today and will be just as preferred tomorrow.”